Potato flakes are a common food ingredient, used not only to make mashed potatoes but also by many food processing companies and bakeries to develop and produce various food products. If you are looking to purchase bulk potato flakes for your own products, here are some tips on selecting the right product.

Suitable Manufacturer for Bulk Potato Flakes

Understand the Manufacturer’s Main Customers and Market

It is crucial to deeply understand the manufacturer to know the typical use cases of their products. For example, a manufacturer focused on producing potato chips might adjust the drying drum temperature during production, resulting in potato flakes that may not be fully cooked. Such flakes are better suited for further processing rather than making mashed potatoes. Therefore, having a deeper understanding of the potato flakes manufacturer can help you choose the right supplier.

Know the Manufacturer’s Production Scale

The production scale of the potato flakes supplier determines whether they can serve large clients and provide a stable supply for small to medium-sized customers.

Check the Factory Location

Many large potato flakes manufacturers have various factories worldwide, often acquired. It’s advisable to know the product’s place of origin to aid your decision-making.

Raw Materials

Understand the Variety of Raw Materials

Potato raw material quality is a core factor affecting the quality of potato flakes. Read my article:

“Potato Flakes | What Potato Varieties are Used for the Production?”

The core quality of the product comes from the raw materials, even though production adjustments can be made through equipment parameters. For instance, using over 80% high-quality Atlantic potatoes as raw material ensures high purity and good color, with these potatoes containing 24% or more dry matter, leading to very high-quality potato flakes.

Storage of Raw Materials

Raw material storage significantly impacts quality, considering factors like disease spread and reducing sugar levels. Large manufacturers usually have a complete raw material supply system, but learning more about this aspect is beneficial.

Understand Raw Material Prices

Potato flakes production involves a raw material input-output ratio where more than 5 kg of high dry matter potatoes produce 1 kg of potato flakes. Raw material cost is the primary factor affecting price, especially if local raw material prices are high. If the potato flakes price hasn’t increased accordingly, the supplier might use different potato varieties for production.

Review the Product’s COA

Key Indicators in the COA

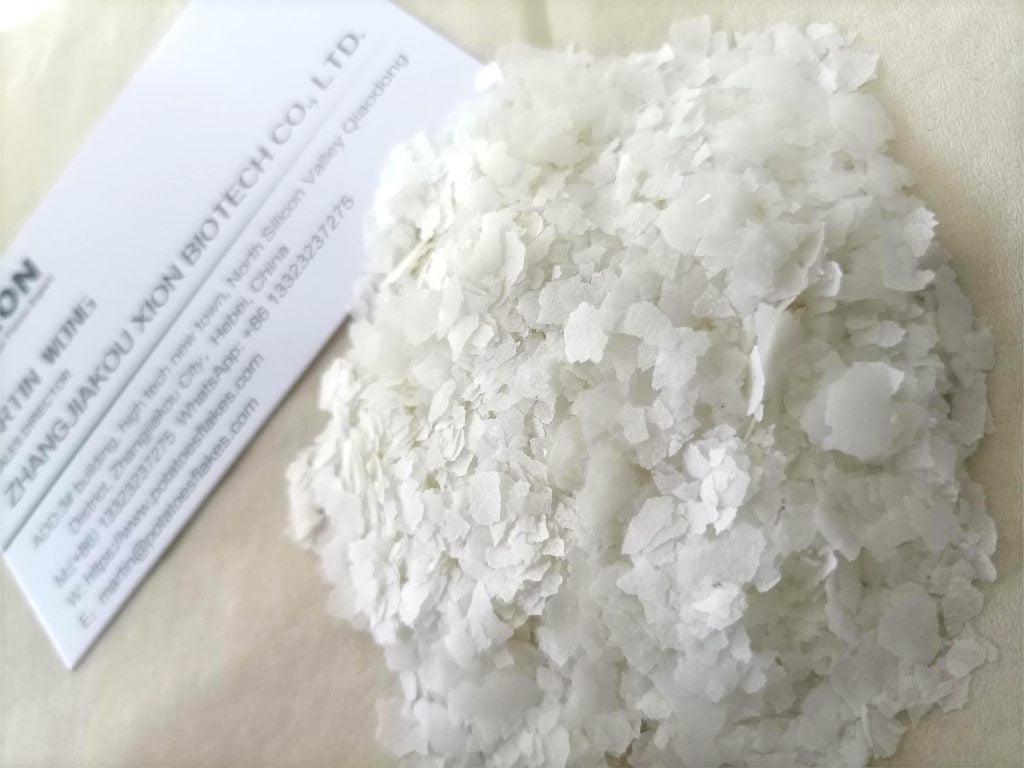

When evaluating potato flakes, consider important indicators such as moisture, reducing sugar, free starch, and blemishes. If these meet the product standards, the product quality is likely good.

Product Testing

Rehydration Test

As a procurement officer, I would first buy samples to conduct quality tests. Prepare a cup of hot water for a rehydration test, gradually sprinkle in potato flakes, and observe the dissolution speed. Alternatively, place a set amount of potato flakes in a cup, quickly pour hot water, and observe the time taken to transform into mashed potatoes. Comparing multiple samples will help identify the best-quality flakes.

Small-scale Trials

After obtaining samples, conduct small-scale trials in the lab according to your product development requirements. Make finished product samples from different raw materials and perform blind tests, which might help you choose the best supplier.

Bulk Potato Flakes Pricing

Product Prices

Price is a significant concern when procuring potato flakes. From my experience and market observation, the reasonable price range for Chinese-produced potato flakes is 1650 USD to 2000 USD per ton. However, due to external factors and a significant rise in raw material prices, prices have recently increased to 2300 USD per ton, posing challenges for small and medium buyers. Our industry forecast suggests prices may decrease, though unforeseen factors could prevent a return to the reasonable range.

Product Transportation

Transportation Costs

To help calculate transportation costs, a 20’ container can hold 8 tons of bagged potato flakes (20 kg per bag), and a 40’ container can hold 15 tons (20 kg per bag). For flavored mashed potato powder, a 20’ container can hold 12 tons, and a 40’ container can hold 22 tons. Truck transport can generally carry 20-25 tons of potato flakes.

I hope these suggestions are helpful for anyone involved in potato flakes procurement. If you have any questions, please feel free to contact me.

It is really helpful. Thank you.

How do I check the quality of potato flakes, any easy method ?

Thank you. It depends on how you will use the potato flakes.

like making mashed potatoes, bakery, or something else.

I suggest you do some experiments before choosing a brand.