เกล็ดมันฝรั่ง เป็นผลิตภัณฑ์ที่ได้จากการคายน้ำและทำให้แห้ง, ทำให้เกิดเป็นขุยหรือเป็นผงละเอียด. เรียกรวมกันว่าผงมันฝรั่งทั้งหมด. ในระหว่างกระบวนการผลิต, ความสมบูรณ์ของเซลล์มันฝรั่งจะยังคงอยู่, คงรสชาติธรรมชาติของมันฝรั่งเอาไว้.

มันฝรั่งเกล็ดคืออะไร?

เกล็ดมันฝรั่ง เป็นอาหารประเภทมันฝรั่งปรุงสุกและอบแห้งและวัสดุสำหรับใช้โดยตรง, การผลิตอาหาร, และผลิตภัณฑ์อื่นๆ.

หลายคนเรียกมันฝรั่งแผ่นเกล็ดว่าผงมันฝรั่ง, แป้งมันฝรั่ง, หรือ ผงมันฝรั่งบด, แต่จริงๆ แล้วมันเป็นผลิตภัณฑ์จากมันฝรั่งที่แตกต่างกัน.

โดยทั่วไป, ผงมันบดมีสามประเภท: เม็ดมันฝรั่ง, เกล็ดมันฝรั่ง, และเกล็ดมันฝรั่งบด (บางคนเรียกมันว่าแป้งมันฝรั่ง).

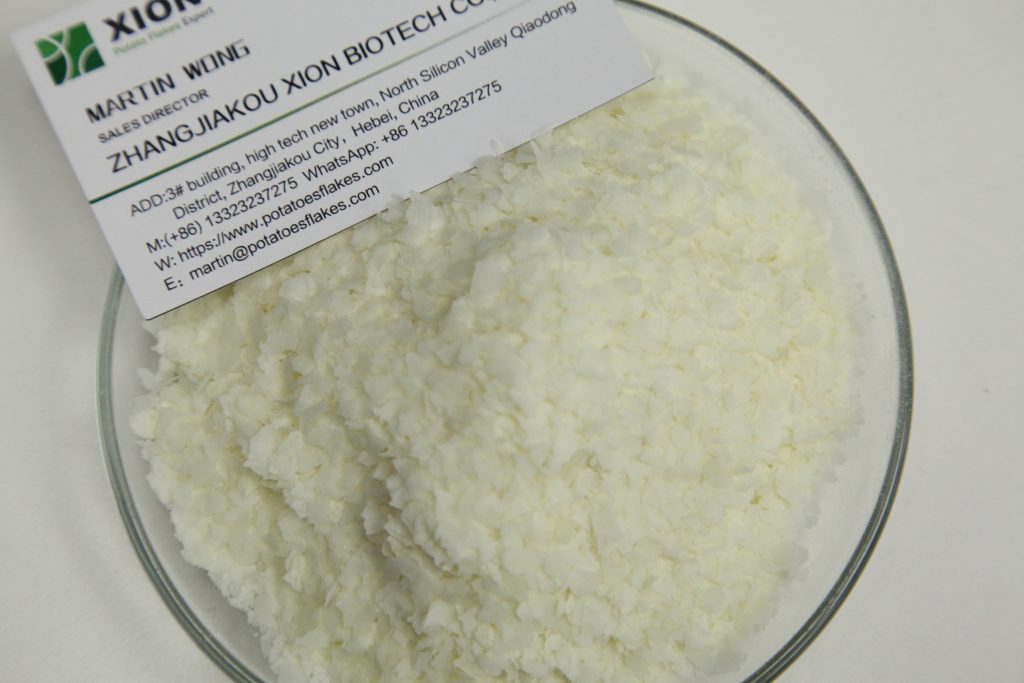

เกล็ดมันฝรั่งสามารถแยกแยะได้ง่ายด้วยสายตา. ปรากฏเป็นเกล็ดคล้ายเกล็ดหิมะ, ส่วนใหญ่เป็นสีเช่นสีขาว, สีเหลืองอ่อน, และสีเหลือง. เกล็ดมันฝรั่งบางชนิดก็มีสีแดงและสีม่วงด้วย. เกล็ดมันฝรั่งไม่ค่อยพบเห็นในซูเปอร์มาร์เก็ตและตลาดท้องถิ่น เนื่องจากมักใช้เป็นส่วนผสมในอาหารว่าง, ขนมอบ, และผลิตภัณฑ์อื่นๆ.

ด้านล่าง, เราจะนำเสนอการเปรียบเทียบผลิตภัณฑ์จากมันฝรั่งทั้งสามประเภทนี้อย่างง่ายๆ.

เม็ด:

- ผลิตด้วยเทคโนโลยีการอบแห้งด้วยลมร้อน.

- มีอยู่ในรูปของเม็ดโมโนเมอร์เซลล์มันฝรั่งหรือมวลรวมของเซลล์หลายเซลล์.

- เรียกย่อว่าผงทั้งเม็ด.

สะเก็ด:

- ผลิตโดยใช้เทคโนโลยีการอบแห้งแบบดรัม.

- เกล็ดไม่สม่ำเสมอมีตั้งแต่ 0.1 ถึง 0.25 หนา มม. และ 3 ถึง 10 เส้นผ่านศูนย์กลาง มม.

- ปกติเราใช้ตะแกรงขนาด 20 ตาข่าย, ซึ่งให้เส้นผ่านศูนย์กลางเฉลี่ยเท่ากับ 3 มม.

แป้ง:

- เราสามารถทำผงมันฝรั่งละเอียดได้โดยการบดผลิตภัณฑ์มันฝรั่งอบแห้ง

- เรียกย่อว่าผงละเอียด.

ผลผลิต: ในบรรดาผงทั้งสามประเภท, เกล็ดมันฝรั่ง, และเม็ดมีผลผลิตสูงสุดในการผลิตจริง. มันฝรั่งแผ่นเป็นผลิตภัณฑ์หลักในประเทศจีนในปัจจุบัน. ผู้ผลิตในยุโรปและอเมริกาหลายรายผลิตเม็ดมันฝรั่งมากกว่าเกล็ดมันฝรั่ง.

มันฝรั่งเกล็ดทำอย่างไร? รายละเอียด

ขั้นตอนการผลิตมันฝรั่งแผ่นเกล็ดจะซับซ้อนเล็กน้อยรวมถึงการเลือกใช้วัตถุดิบ, ซักผ้า, ปอกเปลือก, กำลังเลือก, การหั่น, ล้าง, ก่อนทำอาหาร, ระบายความร้อน, นึ่ง, การบด, การคายน้ำ, และการทำให้แห้ง.

ในกระบวนการทั้งหมด, ขั้นตอนที่สำคัญที่สุดคือ การคัดเลือกวัตถุดิบ, การปอกมันฝรั่ง, การป้องกันสี, และการทำให้แห้ง.

การคัดเลือกวัตถุดิบ:

- ข้อพิจารณาที่สำคัญ: การเลือกพันธุ์มันฝรั่งเป็นสิ่งสำคัญสำหรับการแปรรูปมันฝรั่งแผ่น. พันธุ์ต่างๆ ควรมีปริมาณวัตถุแห้งสูง และมีปริมาณน้ำตาลและสารอันตรายที่รีดิวซ์ต่ำ, มีการงอกน้อยที่สุดและมีสีอ่อน. ควรปราศจากโรคร้ายแรงด้วย.

การปอกมันฝรั่ง:

- ความสำคัญ: ไม่ว่าจะใช้วิธีการประมวลผลใดก็ตาม, จำเป็นต้องปอกเปลือกมันฝรั่งเพื่อให้ได้เกล็ดมันฝรั่งคุณภาพสูง. เปลือกมันฝรั่งมีสารประกอบที่เป็นพิษ เช่น โซลานีนและไนเตรต. การปอกเปลือกจะช่วยลดเนื้อหาของสารประกอบเหล่านี้, รับประกันความปลอดภัยของเกล็ดมันฝรั่ง.

- วิธีการทั่วไป:

- วิธีการปอกเปลือกแบบเดิมส่งผลให้สูญเสียมันฝรั่งอย่างมีนัยสำคัญ, ตั้งแต่ 15% ถึง 50%.

- การปอกเปลือกด้วยไอน้ำเป็นวิธีที่มีประสิทธิภาพมากที่สุด, ก่อเหตุเท่านั้น 4% ถึง 6% การสูญเสีย. อีกทั้งยังมีประสิทธิภาพสูงสุดอีกด้วย, ประมวลผลได้ถึง 3000 มันฝรั่งทุกๆ 6 วินาที.

การป้องกันสี:

- มุมมองที่สำคัญ: การปกป้องสีเป็นสิ่งสำคัญสำหรับรูปลักษณ์และคุณภาพของเกล็ดมันฝรั่ง.

- การก่อตัวของสารประกอบควิโนน: ขั้นตอนการประมวลผล เช่น การปอกเปลือกและการหั่นอาจทำให้เซลล์เสียหายได้, นำไปสู่การก่อตัวของสารประกอบควิโนนจากโพลีฟีนอลออกซิเดสที่ทำปฏิกิริยากับโพลีฟีนอล. สารประกอบควิโนนเหล่านี้สามารถทำปฏิกิริยากับกลุ่มกรดอะมิโนในเซลล์มันฝรั่งได้อีก, ส่งผลให้มีสีน้ำตาล.

- วิธีการที่มีประสิทธิภาพ:

- วิธีการที่มีประสิทธิภาพมากที่สุดคือการผสมสารป้องกันสีเพื่อควบคุมการใช้งานและรับประกันประสิทธิภาพ. ตัวอย่างเช่น, การผสมผสานกรดซิตริกและดีโซเดียมอิริทอร์เบตช่วยเพิ่มการปกป้องสี. ผสมผสานวิตามินซี, กรดไฟติก, กรดซิตริก, และแอล-ซิสเทอีนยับยั้งการเกิดสีน้ำตาลได้อย่างมีประสิทธิภาพ, บรรลุการปกป้องสีที่เหมาะสมที่สุด.

ทำให้มันฝรั่งบดแห้ง

- การอบแห้งด้วยลมร้อนและการอบแห้งแบบแช่แข็งแบบสุญญากาศเป็นสองวิธีหลักในการอบแห้งมันฝรั่งบด.

การอบแห้งแบบดรัม:

- วิธีที่ใช้กันอย่างแพร่หลาย: การอบแห้งแบบดรัมเป็นวิธีการหลักในการอบแห้งเกล็ดมันฝรั่ง.

- อิทธิพลของอุณหภูมิการทำให้แห้ง: ปริมาณน้ำตาลรีดิวซ์ในเกล็ดมันฝรั่งที่ทำด้วยการอบแห้งด้วยลมร้อนได้รับผลกระทบอย่างมากจากอุณหภูมิในการทำให้แห้ง. เมื่ออุณหภูมิสูงขึ้น, ปริมาณน้ำตาลรีดิวซ์จะเพิ่มขึ้นก่อน, จากนั้นก็ตก. ขณะเดียวกัน, ปริมาณวิตามินซีจะลดลงเมื่ออุณหภูมิในการทำให้แห้งเพิ่มขึ้น.

- ข้อเสีย: ในขณะที่การอบแห้งแบบดรัมนั้นง่ายและคุ้มค่า, มันทำลายโครงสร้างจุลภาคของมันฝรั่ง, ยับยั้งความชื้นและน้ำมันซึมผ่านและลดการทำงานร่วมกัน. นอกจากนี้ยังส่งผลให้ความขาวลดลงและระดับการเกิดสีน้ำตาลและการเกิดออกซิเดชันในเกล็ดมันฝรั่งในระดับต่างๆ.

วิธีทำเกล็ดมันฝรั่งที่บ้าน?

การผลิตในระดับอุตสาหกรรมต้องใช้อุปกรณ์และกระบวนการพิเศษเพื่อให้มั่นใจในคุณภาพที่ขายได้. อย่างไรก็ตาม, คุณสามารถทำปริมาณเล็กน้อยที่บ้านได้. แต่การทำเกล็ดมันฝรั่งด้วยมือนั้นยากมาก, ผลลัพธ์จะเหมือนแป้งมันฝรั่งมากขึ้น. คุณยังสามารถลองสิ่งนี้ได้:

- เลือกมันฝรั่งสด.

- ปอกมันฝรั่ง.

- นึ่งหรือต้มมันฝรั่งจนนิ่ม.

- บดมันฝรั่งที่ปรุงสุกแล้วให้เป็นน้ำซุปข้น.

- เกลี่ยมันฝรั่งบดเป็นแผ่นบางๆ.

- อบหรือไมโครเวฟจนแห้ง.

- รวบรวมและบดมันฝรั่งบดแห้งเพื่อทำเป็นเกล็ดมันฝรั่ง.

บันทึก: โดยทั่วไปอัตราส่วนของมันฝรั่งต่อเกล็ดมันฝรั่ง 5:1, ความหมาย 5 มันฝรั่งให้ผลผลิตประมาณกิโลกรัม 1 กิโลกรัมมันฝรั่งเกล็ด.